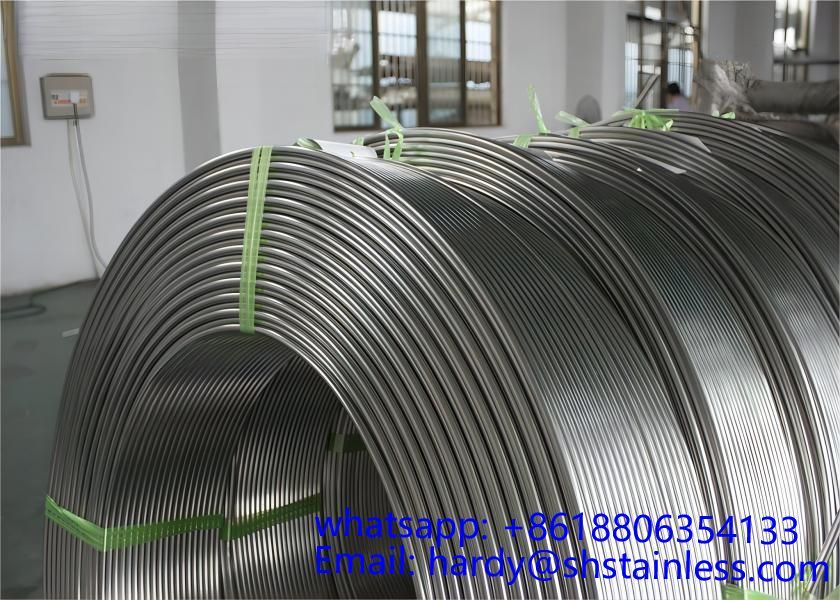

2507 igwe anaghị agba nchara 10 * 1mm mkpuchi mkpuchi capillary

Nkọwa ihe onwunwe

2507 igwe anaghị agba nchara 10 * 1mm mkpuchi mkpuchi capillary

Ihe niile anyị nwere nnukwu duplex bụ Norsok M-650 Ed.4 na/ ma ọ bụ ISO 17782 ndị nrụpụta ruru eru.

Super Duplex UNS S32750 bụ ọkwa super duplex kachasị na ahịa.UNS S32750 bụ duplex emebere maka ọrụ na gburugburu chloride nwere ike ike.Ọ nwere ezigbo nguzogide corrosion mpaghara na nrụgide corrosion cracking yana nchikota na ike igwe dị elu.A na-eji ya na mmanụ & gas, ike mmiri, ụgbọ mmiri nrụgide, pulp & akwụkwọ, ihe nhazi na tankị kemịkalụ.

Ngwa

2507 igwe anaghị agba nchara 10 * 1mm mkpuchi mkpuchi capillary

Ngwa ndị bụ isi bụ maka nkọwa na ihe ndị pụrụ iche chọrọ maka nguzogide corrosion dị elu.

E ji mara UNS S32750 site na:

- Nnukwu iguzogide nrụgide corrosion mgbawa na halide nwere gburugburu.

- Nnukwu iguzogide pitting na crevice corrosion.

- Nnukwu iguzogide corrosion izugbe.

- Ike igwe dị elu.

- Mgbochi dị elu maka mmebi mmebi na ike ọgwụgwụ corrosion.

Okpomọkụ ọgwụgwọ2507 igwe anaghị agba nchara 10 * 1mm gbakọtara capillary tubing

Ngwọta annealing na nso nke 1100 Celsius C na-esote mmiri quenching.

Weldability

Ọ dị ezigbo mma.

2507 igwe anaghị agba nchara 10 * 1mm mkpuchi mkpuchi capillary

Ngwakọta kemịkalụ (kpọmkwem maka ụlọ mmanya)

| Ibu % | C | Mn | P | S | Si | Cr | Ni | Mo | Ku | N | PRE |

| Min. | 24,0 | 6,00 | 3,00 | 0,24 | 41 | ||||||

| Oke. | 0,030 | 1,20 | 0,025 | 0,010 | 0,80 | 26,0 | 8,00 | 4,50 | 0,50 | 0,32 |

PREN = % Cr + 3.3 % Mo + 16 % N ≥ 41

Ụkpụrụ ntụaka

Izugbe:

- Norsok M-650 Ed.4 ndị nrụpụta ruru eru

- PED 2014/68/EU Mgbakwunye I ngalaba 4.3

- AD2000 W0 (W2/W10)

- NACE MR0175/ ISO 15156-3 na NACE MR0103/ISO 17945

- 2507 igwe anaghị agba nchara 10 * 1mm mkpuchi mkpuchi capillary

Efere, mpempe akwụkwọ na eriri igwe:

- ASTM A240, EN 10028-7, EN 10088-2, EN 10088-4, Norsok M-630 MDS D55

Ogwe na ịgha:

- ASTM A276, ASTM A479, ASTM A182, EN 10088-3, Norsok M-630 MDS D54/D57

Ngwaahịa ndị ọzọ:

- Dị ka ọdabara ASTM na/ma ọ bụ EN ụkpụrụ na Norsok M-630 MDS

Ngwongwo igwe (nke a na-ahụkarị)

| Mpụta ike Rp0.2, MPa | Ike tensile Rm, MPa | Ogologo oge [%] | Isi ike [HB] | Mmetụta, Charpy-V, -46ºC [J] | |

| Ogwe | ≥ 550 | 750 | ≥ 25 | ≤300 | ≥ 65 |

| Efere CR (Ọkụkụ) | ≥ 550 | 750-1000 | ≥ 25 | ≤310 | ≥ 45 |

| Efere HR (COIL) | ≥ 550 | 750-1000 | ≥ 25 | ≤310 | ≥ 45 |

| Efere (QUARTO) | ≥ 550 | 750-930 | ≥ 25 | ≤310 | ≥ 45 |