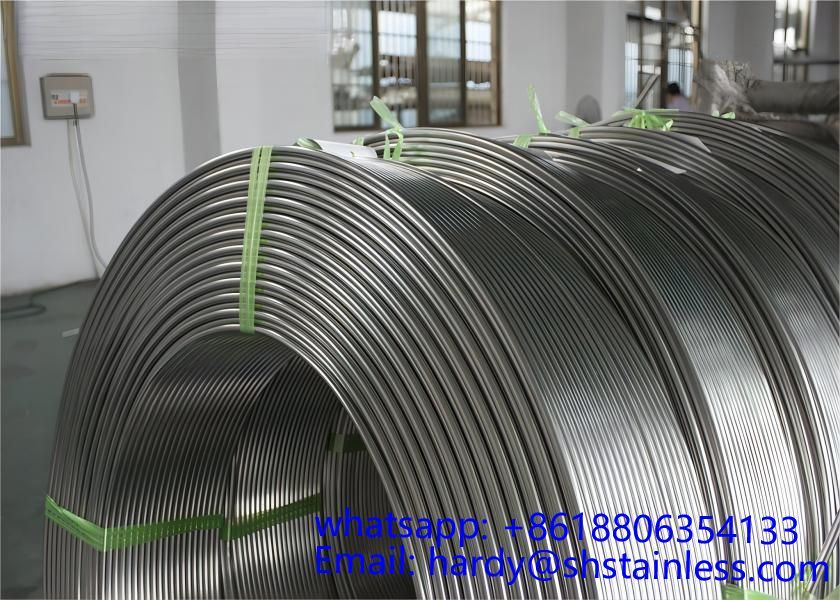

254SMO igwe anaghị agba nchara 9.53 * 1.24 ọkpọkọ ọkpọkọ

Ụkpụrụ mba:UNS S31254, DIN/EN 1.4547, ASTM A280, ASME SA-280

Ihe na-akwado ịgbado ọkụ:ErNICRMO-3 waya, EICCRmo-3 electrode

Ngwakọta kemịkalụ:

254SMO igwe anaghị agba nchara 9.53 * 1.24 ọkpọkọ ọkpọkọ

| Ọkwa | % | Ni | Cr | Mo | Cu | N | C | Mn | Si | P | S |

| 254SMO | MIN | 17.5 | 19.5 | 6 | 0.5 | 0.18 | |||||

| MAX | 18.5 | 20.5 | 6.5 | 1 | 0.22 | 0.02 | 1 | 0.8 | 0.03 | 0.01 |

Nnukwu okpomọkụ na-eguzogide

254SMO igwe anaghị agba nchara 9.53 * 1.24 ọkpọkọ ọkpọkọ

1. Nnukwu nnwale ubi na ahụmahụ dị ukwuu egosila na ọbụna na okpomọkụ dị elu dị elu, 254SMO nwere nnukwu nguzogide crevice-corrosion na mmiri mmiri, nke naanị ụdị igwe anaghị agba nchara nwere.

2. 254SMO si corrosion eguzogide na acidic na oxidizing halide ngwọta dị ka ndị chọrọ maka akwụkwọ bleaching mmepụta bụ tụnyere nke ndị kasị eguzogide nickel-base na titanium alloys.

3. N'ihi ọdịnaya nitrogen dị elu, 254SMO nwere ike ịrụ ọrụ dị elu karịa ụdị austenitic igwe anaghị agba nchara.Na mgbakwunye, 254SMO nwere nnukwu ductility na ike mmetụta yana ezigbo weldability.

4. The elu molybdenum ọdịnaya nke 254SMO na-enyere ya aka inwe elu ọxịdashọn ọnụego na annealing, na-akpata a rougher elu karịa nkịtị igwe anaghị agba nchara mgbe pickling.Ma nke a enweghị mmetụta ọjọọ na nguzogide corrosion nke ígwè.

Ngwa:

254SMO igwe anaghị agba nchara 9.53 * 1.24 ọkpọkọ ọkpọkọ

1. Oke osimiri: Ihe owuwu mmiri na gburugburu mmiri mmiri, mmiri mmiri na-ekpochapụ mmiri, ihe ọkụkụ, mgbanwe okpomọkụ nke mmiri mmiri, dị ka ọkpọkọ mmiri na-ekpo ọkụ na-eme ka mmiri dị nro na-eme ka mmiri dị n'oké osimiri dị n'ime ụlọ ọrụ ọkụ, ihe eji eme ihe, ọbụna na ngwá ọrụ ebe mmiri mmiri nwere ike ọ gaghị eru, wdg.

2. Environmental nchebe ubi: thermal ike ọgbọ flue gas desulfurization ngwaọrụ, n'efu mmiri ọgwụgwọ, isi akụkụ bụ: absorber tower ahụ, flue, ụzọ ogwe, n'ime akụkụ, ịgba usoro, wdg.

3. Ike: atomiki ike mmepụta, keukwu itinye n'ọrụ nke coal, tidal ike ọgbọ, wdg.

4. Ụlọ ọrụ Petrochemical: mmanụ na-edozi mmanụ, akụrụngwa kemịkalụ, akụrụngwa petrochemical, dị ka mgbịrịgba na akụrụngwa petrochemical, wdg.

5. Ebe nri: Ime nnu, ụlọ ọrụ na-eme ka mmiri na-ekpo ọkụ, dị ka ime nnu ma ọ bụ ihe eji eme ka mmiri na-esi ísì ụtọ, nsị soy sauce, wdg.

6. Ebe nchekwa ion chloride dị elu: ụlọ ọrụ na-emepụta akwụkwọ, pulp na akụrụngwa ịcha ọcha akwụkwọ, dị ka ndị na-agbaze pulp, akụrụngwa ịcha ọcha, nzacha ihe nzacha na igwe na-akpụ akpụ na akụrụngwa ịcha ọcha ndị ọzọ.