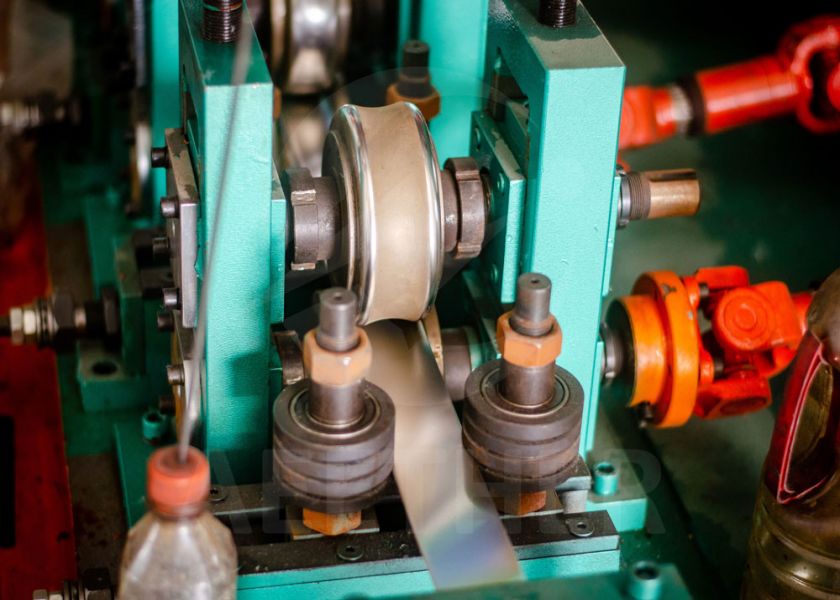

321 igwe anaghị agba nchara 5 * 1.2mm capillary tubing

Alloy 321 (UNS S32100) bụ a

titanium kwụsiri ike austenitic

igwe anaghị agba nchara na ezi izugbe

iguzogide corrosion.Ọ nwere oke

iguzogide corrosion intergranular

mgbe ikpughe na okpomọkụ na

chromium carbide mmiri ozuzo

321 igwe anaghị agba nchara 5 * 1.2mm capillary tubing

oke nke 800–1500°F (427–816°C).

Alloy na-eguzogide oxidation ruo 1500 ° F

(816ºC) ma na-akpụ akpụ dị elu

Njirimara mgbawa nrụgide karịa alloys

304 na 304L.O nwekwara

ezigbo obere okpomọkụ siri ike.

Alloy 321H (UNS S32109) bụ

ụdị carbon dị elu (0.04-0.10) nke

ihe alloy.E mepụtara ya maka

enwekwukwa creep nguzogide na maka

ike dị elu na okpomọkụ

n'elu 1000°F (537°C).N'ọtụtụ

ihe atụ, carbon ọdịnaya nke

efere na-enyere asambodo abụọ aka.

Alloy 321 enweghị ike ime ka ọ sie ike

ọgwụgwọ okpomọkụ, naanị site na ịrụ ọrụ oyi.

Ọ nwere ike mfe welded na

esichara site ọkọlọtọ ụlọ ahịa

omume imepụta ihe.

Ngwa

• Aerospace

- igwe piston

manifolds

• Nhazi kemịkalụ

• Mgbasa nkwonkwo

• Nhazi nri—ngwaọrụ

na nchekwa

• Nnụcha mmanụ ala—polythionic

ọrụ acid

• Ọgwụgwọ mkpofu—ọkụ

oxidizers

Ụkpụrụ

321 igwe anaghị agba nchara 5 * 1.2mm capillary tubing

ASTM …………………………. A 240

ASME …………………. SA 240

AMS ………………………….5510

Nyocha kemịkalụ

Ibu % (ụkpụrụ niile kacha belụsọ ma egosighi oke)

Mpempe akwụkwọ nkọwapụta: Alloy 321/321H

(UNS S32100, S32109) W. Nr.1.4541

Titanium Stabilized Austenitic igwe anaghị agba nchara nwere ezigbo nguzogide

na Intergranular corrosion Mgbe ekpughere na okpomọkụ na

Oke mmiri ozuzo Chromium Carbide nke 800–1500°F (427–816°C)

321 igwe anaghị agba nchara 5 * 1.2mm capillary tubing

Alloy 321 06/2014

Nkpughe 02/2023 PDF njikọ

Njirimara anụ ahụ

Njupụta

0.286 lbs / n'ime 3

7.920 g/cm3

Modul nke Elasticity

28.0 x 106 psi

193 GPA

Oke agbaze

2550–2635°F

1398–1446°C

Okpomọkụ akọwapụtara

0.12 BTU/lb-°F (32–212°F)

500 J/kg-°K (0–100°C)

Mmetụta okpomọkụ 212°F (100°C)

9.3 BTU/hr/ft2/ft/°F

16.0 W/m-°K

Eletriki Resistivity

72 Microhm-cm na 20 Celsius

Ihe eji arụ ọrụ

Ọnụ ahịa a na-ahụkarị na 68°F (20°C)

Oke okpomọkụ

°F

Celsius C

na/na Celsius F

cm/cm Celsius C

68–212

20–100

9.2 x 10-6

16.0 x 10-6

68–1112

20–600

10.5 x 10-6

18.9 x 10-6

68–1832

20–1000

11.4 x 10-6

20.5 x 10-6

Mpụta Ike

Oke tensile

Ogologo oge

Isi ike

0.2% kwụsịrị

Ike

na 2 in.

psi (min.)

(MPa)

psi (min.)

(MPa)

% (nkeji)

(max.)

30,000

205

75,000

515

40

217 Brinell

Dee ozi gị ebe a ziga anyị ya