Ọnụ ahịa eriri igwe anaghị agba nchara 600 Alloy

Ngwakọta kemịkalụ,%

Ngwa nrụrụ a na-ahụkarị gụnyere mmepụta titanium dioxide (ụzọ chloride), njikọ perchlorethylene, vinyl chloride monomer (VCM), na magnesium chloride.Alloy 600 na-eji kemịkalụ na mmepụta nri na nchekwa, ọgwụgwọ okpomọkụ, condensers phenol, imepụta ncha, ihe oriri na arịa acid fatty na ọtụtụ ndị ọzọ.

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 min | 14.0-17.0 | 6.0-10.0 | .15 kacha | 1.00 kacha | .015 kacha | .50 kacha | .50 kacha |

N'ime ngwa ndị a na-eji Inconel 600?

- Ụlọ ọrụ kemịkalụ

- Igwe ikuku

- Ụlọ ọrụ ọgwụgwọ okpomọkụ

- Pulp na ụlọ ọrụ akwụkwọ

- Nhazi nri

- Injinia nuklia

- Ngwa ngwa turbine gas

Nkọwa ASTM

| Pipe SMS | Ọkpọkpọ Weld | Tube SMS | Tube Weld | Mpempe akwụkwọ/efere | Ogwe | Na-akpụ akpụ | Kwesịrị ekwesị | Waya |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Ihe eji arụ ọrụ

Àgwà ọma tensile okpomọkụ nke ime ụlọ nke Annealed Material

| Ụdị ngwaahịa | Ọnọdụ | Tensile (ksi) | .2% Mpụta (ksi) | Mgbatị (%) | Isi ike (HRB) |

| Mkpanaka & mmanya | Oyi-Dọrọ | 80-100 | 25-50 | 35-55 | 65-85 |

| Mkpanaka & mmanya | Na-ekpo ọkụ-Emechara | 80-100 | 30-50 | 35-55 | 65-85 |

| Ọkụ & Ọkụ | Na-ekpo ọkụ-Emechara | 75-100 | 25-50 | 35*55 | - |

| Ọkụ & Ọkụ | Oyi-Dọrọ | 80-100 | 25-50 | 35-55 | 88 Max |

| Efere | Na-ekpo ọkụ | 80-105 | 30-50 | 35-55 | 65-85 |

| Mpempe akwụkwọ | Oyi-Dọrọ | 80-100 | 30-45 | 35-55 | 88 Max |

Inconel 600 Melting Point

| Ihe | Njupụta | Ebe Na-agbaze | Ike ọdụdọ | Ike Mpụta (0.2% kwụsịrị) | Ogologo oge |

| Alloy 600 | 8.47 g/cm3 | 1413 Celsius (2580 Celsius) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40% |

Inconel 600 Dakọtara

| Ọkọlọtọ | Ọrụ NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Alloy 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15F |

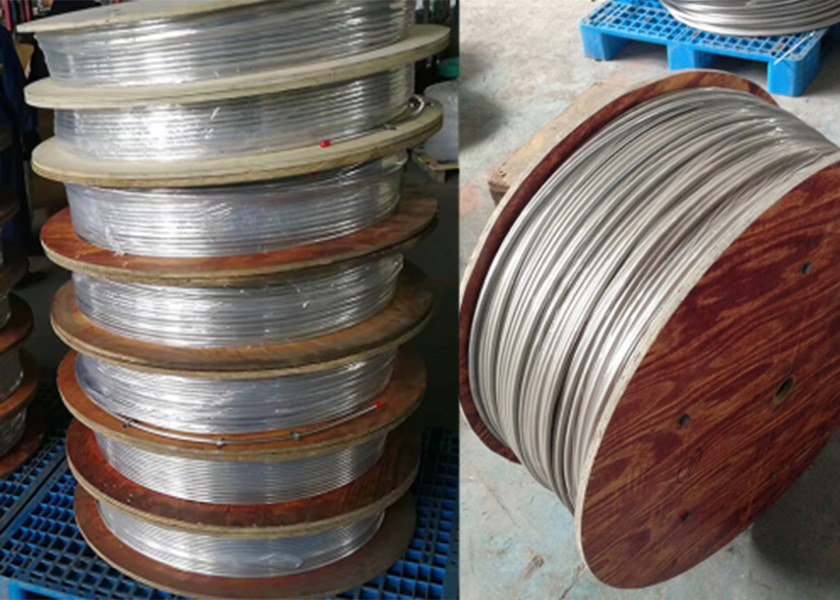

Alloy 600 tubing

Alloy 600 bụ ezigbo onye ndoro-ndoro maka ọtụtụ ojiji na oke okpomọkụ na gburugburu ebe na-emebi emebi.Ngwakọta nke nickel na chromium na-ebute nguzogide siri ike na oxidation na okpomọkụ na-arụ ọrụ.Okpomọkụ ndị a nwere ike ịdị site na cryogenic ruo ọkwa na-ekpo ọkụ nke 2,000ºF.Ọdịnaya nickel dị elu nke alloy 400 na-enyekwa ihe fọrọ nke nta ka ọ bụrụ nkwụsi ike zuru oke maka mgbawa corrosion corrosion, nke a na-ahụkarị na gburugburu chloride.

Ọ dị mkpa iburu n'obi na akụkụ chromium nke profaịlụ kemịkalụ alloy na-eme ka o kwe omume na ọkwa ahụ na-eguzogide okpomọkụ dị elu.Ọdịdị ọka kachasị mma nke tube oyi gwụchara, gbakwunyere, na-eweta nguzogide corrosion ka mma, nke gụnyere ike ọgwụgwụ dị elu na mmetụta ike ụkpụrụ.

Nkọwapụta ngwaahịa

ASTM B163, B167 / ASME SB163 / NACE MR0175, MR0103

Oke Oke

| Dayameta dị n'èzí (OD) | Ọkpụrụkpụ mgbidi |

| .250”–.750” | .035”–083” |

Ihe achọrọ kemịkalụ

Alloy 600 (UNS N06600)

Ihe mejupụtara%

| Ni Nickel | Cu Ọla kọpa | Fe Ígwè | Mn Manganese | C Carbon | Si Silikoni | S sọlfọ | Cr Chromium |

| 72.0 min | 0.50 kacha | 6.00-10.00 | 1.00 kacha | 0.15 kacha | 0.50 kacha | 0.015 kacha | 14.0–17.0 |

Nlere anya akụkụ

| OD | OD ndidi | Nkwenye mgbidi |

| ≤ .500” ewepu | + .005” | ± 12.5% |

| .500”-.750” ewepu | + .005” | ± 12.5% |

Ihe eji arụ ọrụ

| Ike Mpụta: | 35 ksi min |

| Ike ọdụdọ: | 80 ksi min |

| Mgbatị (nkeji 2): | 30% |

Imepụta

Alloy 600 nwere ike mfe welded site ọkọlọtọ usoro.The njikwa nke alloy a magburu onwe ya, na-ebi n'etiti ịba uru nke T303 na T304.

Foto ụlọ ọrụ

Nyocha

Mbupu & mbukota

Akụkọ nnwale