Alloy 625 igwe anaghị agba nchara tubing ọnụ ahịa

Ngwakọta kemịkalụ,%

Alloy 625 ihe na-abụghị magnetik, austenitic, ma na-egosiputa ike tensile dị elu, nrụpụta na brazeability.N'ihi nnukwu ọdịnaya nickel ya, alloy a fọrọ nke nta ka ọ ghara ịnweta chloride ion stress-corrosion cracking and pitting, nke a na-ahụkarị na ọla n'ime ngwa mmiri dị n'oké osimiri dị ka ndị na-ekpo ọkụ, ihe nkwụnye ọkụ, na ịkwanye eriri.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Ihe fọdụrụ | 8.0-10.0 | 1.0 kacha | 3.15-4.15 | .40 kacha | .40 kacha | .10 kacha |

| Fe | Mn | Si | P | S |

| 5.0 kacha | .50 kacha | .50 kacha | .015 kacha | .015 kacha |

N'ime ngwa ndị a na-eji Inconel 625?

- A na-eji Inconel 625 eme ihe na ụlọ ọrụ Aerospace

- Sistemụ ducting ụgbọ elu

- Sistemụ iyuzucha ụgbọ elu

- Sistemụ ihe ngbanwe nke igwe

- Ngwá ọrụ mmiri mmiri pụrụ iche

- Ngwá ọrụ usoro kemịkalụ

Nkọwa ASTM

| Pipe SMS | Ọkpọkpọ Weld | Tube SMS | Tube Weld | Mpempe akwụkwọ/efere | Ogwe | Na-akpụ akpụ | Kwesịrị ekwesị | Waya |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Ihe eji arụ ọrụ

| Okpomọkụ ° F | Tensile (psi) | .2% Mpụta (psi) | Mgbatị n'ime 2 "(%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Inconel 625 Ebe Mgbaze

| Ebe Na-agbaze | 1290 - 1350 Celsius | 2350 - 2460 °F |

Inconel 625 Dakọtara

| Ọkọlọtọ | Ọrụ NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2,4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

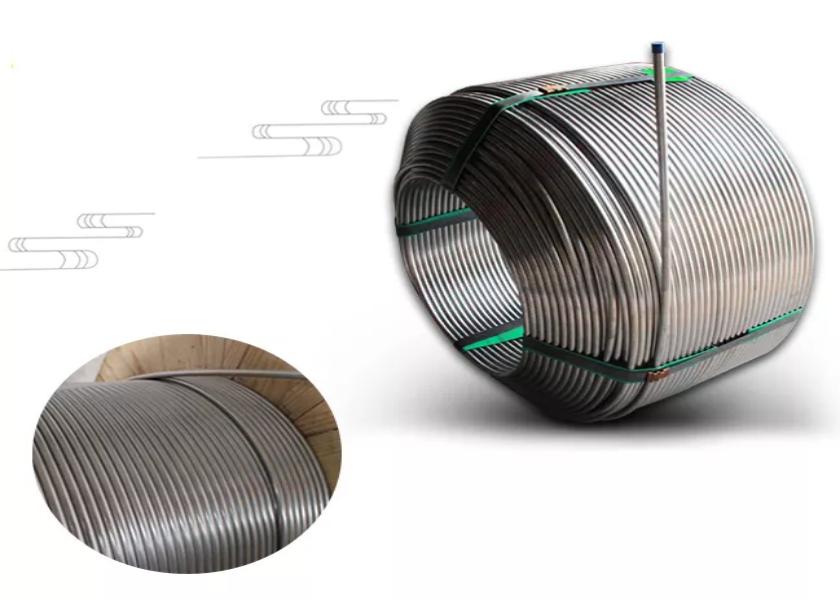

Alloy 625 tubing

Alloy 625 bụ austenitic nickel-chromium-molybdenum superalloy mara maka iguzogide corrosion crevice na oxidation na okpomọkụ dị elu.Okpomọkụ ndị a nwere ike ịdị site na cryogenic ruo n'ogo dị oke ọkụ nke 1,800°F.Omume na ihe mejupụtara kemịkalụ nke ọkwa a na-eme ka ọ dabara nke ọma maka ngwa nuklia na ikuku.Ọzọkwa, na mgbakwunye na nke niobium, alloy 625 tubing na-ahụ onwe ya na-abawanye ike na-enweghị okpomọkụ ọgwụgwọ.Ngwongwo a na-eme ka ọkwa ahụ bụrụ nhọrọ magburu onwe ya maka ịmepụta.

Nkọwapụta ngwaahịa

ASTM B444 / ASME SB444 / NACE MR0175

Oke Oke

| Dayameta dị n'èzí (OD) | Ọkpụrụkpụ mgbidi |

| .375"-.750" | .035”–095” |

Ihe achọrọ kemịkalụ

Alloy 625 (UNS N06625)

Ihe mejupụtara%

| C Carbon | Mn Manganese | Si Silikoni | P Phosphorous | Cr Chromium | Nb+Ta Niobium-Tantalum | Co Cobalt | Mo Molybdenum | Fe Ígwè | Al Aluminom | Ti Titanium | Ni Nickel |

| 0.10 kacha | 0.50 kacha | 0.50 kacha | 0.015 kacha | 20.0–23.0 | 3.15–4.15 | 1.0 kacha | 8.0–10.0 | 5.0 kacha | 0.40 kacha | 0.40 kacha | 58.0 min |

Nlere anya akụkụ

| OD | OD ndidi | Nkwenye mgbidi |

| .375"-0.500" ewezuga | +.004”/-.000” | ± 10% |

| 0.500"-1.250" ewepu | +.005”/-.000” | ± 10% |

Ihe eji arụ ọrụ

| Ike Mpụta: | 60 ksi min |

| Ike ọdụdọ: | 120 ksi min |

| Mgbatị (nkeji 2): | 30% |

Foto ụlọ ọrụ

Nyocha

Mbupu & mbukota

Akụkọ nnwale