Ti 2 Ọnụ ego tubing Coil

Ihe mejupụtara Titanium

| Ọkwa | Nkọwa |

| Titanium ọkwa 1 | titanium na-adịghị mma, obere oxygen, obere ike |

| Titanium ọkwa 2 | Unalloyed titanium, ọkọlọtọ oxygen, ọkara ike |

| Titanium ọkwa 3 | Unalloyed titanium, ọkara oxygen, elu ike |

| Titanium ọkwa 4 | titanium na-adịghị mma, oxygen dị elu, ike dị elu |

| Titanium ọkwa 5 | Titanium alloy (6% aluminum, 4% vanadium) |

| Titanium ọkwa 7 | Titanium na-enweghị atụ gbakwunyere 0.12% ruo 0.25% palladium, oxygen ọkọlọtọ, ike ọkara |

| Titanium ọkwa 9 | Titanium alloy (3% aluminum, 2.5% vanadium), ike dị elu.Ọ kachasị ngwa ikuku |

| Titanium ọkwa 11 | titanium na-adịghị mma gbakwunyere 0.12% ruo 0.25% palladium, oxygen dị ala, ike dị ala |

| Titanium ọkwa 12 | Titanium alloy (0.3% molybdenum, 0.8% nickel), ike dị elu |

| Titanium ọkwa 13 | Titanium alloy (0.5% nickel, 0.05% ruthenium), obere oxygen |

| Titanium ọkwa 14 | Titanium alloy (0.5% nickel, 0.05% ruthenium), oxygen ọkọlọtọ |

| Titanium ọkwa 15 | Titanium alloy (0.5% nickel, 0.05% ruthenium), ọkara oxygen |

| Titanium ọkwa 16 | Titanium na-enweghị atụ gbakwunyere 0.04% ruo 0.08% palladium, oxygen ọkọlọtọ, ike ọkara |

| Titanium ọkwa 17 | Titanium na-enweghị atụ gbakwunyere 0.04% ruo 0.08% palladium, oxygen dị ala, ike dị ala |

| Titanium ọkwa 18 | Titanium alloy (3% aluminum, 2.5% vanadium gbakwunyere 0.04% ruo 0.08% palladium), |

| Titanium ọkwa 19 | Titanium alloy (3% aluminum, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum) |

| Titanium ọkwa 20 | Titanium alloy (3% aluminum, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum) gbakwunyere 0.04% ka 0.08% palladium |

| Titanium ọkwa 21 | Titanium alloy (15% molybdenum, 3% aluminum, 2.7% niobium, 0.25% silicon) |

| Titanium ọkwa 23 | Titanium alloy (6% aluminum, 4% vanadium, extra ala interstitial, ELI) |

| Titanium ọkwa 24 | Titanium alloy (6% aluminum, 4% vanadium) gbakwunyere 0.04% ruo 0.08% palladium |

| Titanium ọkwa 25 | Titanium alloy (6% aluminum, 4% vanadium) gbakwunyere 0.3% ka 0.8% nickel na 0.04% ka 0.08% palladium |

| Titanium ọkwa 26 | Unalloyed titanium gbakwunyere 0.08% ka 0.14% ruthenium, ọkọlọtọ oxygen, ọkara ike |

| Titanium ọkwa 27 | Unalloyed titanium gbakwunyere 0.08% ka 0.14% ruthenium, ala oxygen, ala ike |

| Titanium ọkwa 28 | Titanium alloy (3% aluminum, 2.5% vanadium) gbakwunyere 0.08% ka 0.14% ruthenium |

| Titanium ọkwa 29 | Titanium alloy (6% aluminum, 4% vanadium na extra ala interstitial element (ELI) gbakwunyere 0.08% ka 0.14% ruthenium |

Nkọwapụta Titanium & Titanium Alloys MIL-T

| AMS-T-9046 (E bipụtara 1999) | |

| Titanium dị ọcha nke azụmahịa | |

| Koodu (CP) | Ike Mpụta (min. ksi) |

| CP-1 | (70 KSI-YS) |

| CP-2 | (55 KSI-YS) |

| CP-3 | (40 KSI-YS) |

| CP-4 | (30 KSI-YS) |

| Alfa Titanium Alloys (A) | |

| CODE | Ihe mejupụtara |

| A-1 | 5AL-2.5Sn |

| A-2 | 5AL-2.5Sn (ELI) |

| A-3 | 6AL-2Cb-1Ta-0.8Mo |

| A-4 | 8AL-1Mo-1V |

| Alfa-Beta Titanium Alloy | |

| (AB) CODE | Ihe mejupụtara |

| AB-1 | 6 AL-4V |

| AB-2 | 6AL-4V (ELI) |

| AB-3 | 6AL-6V-2Sn |

| AB-4 | 6AL-2Sn-4Zr-2Mo |

| AB-5 | 3.AL-2.5V |

| AB-6 | 8Nn |

| Beta Titanium Alloys (B) | |

| CODE | Ihe mejupụtara |

| B-1 | 13V-11Cr-3AL |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3AL-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3AL |

ASTM B338

Oke Oke

| Dayameta dị n'èzí (OD) | Ọkpụrụkpụ mgbidi |

| .125"-.500" | .035" |

Ihe achọrọ kemịkalụ

Titanium ọkwa 2 (UNS R50400)

Ihe mejupụtara%

| N Nitrogen | C Carbon | H Hydrogen | Fe Ígwè | O Oxygen | Ihe fọdụrụ Nke ọ bụla | Ihe fọdụrụ Mkpokọta | Ti Titanium |

| 0.03 kacha | 0.08 kacha | 0.015 kacha | 0.30 kacha | 0.25 kacha | 0.10 kacha | 0.4 kacha | Nhazi |

Nlere anya akụkụ

| OD | OD ndidi | Nkwenye mgbidi |

| .125"-.500" | + .003” | ± 10% |

Ihe eji arụ ọrụ

| Ike Mpụta: | 40 ksi min |

| Ike ọdụdọ: | 50 ksi min |

| Mgbatị (nkeji 2): | 20% |

| Isi ike (oke Rockwell B) | 80 HRB kacha |

Nhọpụta ndị ọzọ

Edepụtara aha ndị ọzọ dabara na ọkwa 310S igwe anaghị agba nchara na tebụl na-esonụ.

| AMS 5521 | ASTM A240 | ASTM A479 | DIN 1.4845 |

| AMS 5572 | ASTM A249 | ASTM A511 | QQ S763 |

| AMS 5577 | ASTM A276 | ASTM A554 | ASME SA240 |

| AMS 5651 | ASTM A312 | ASTM A580 | ASME SA479 |

| ASTM A167 | ASTM A314 | ASTM A813 | SAE 30310S |

| ASTM A213 | ASTM A473 | ASTM A814 | SAE J405 (30310S) |

Alloy 310s igwe anaghị agba nchara eriri igwe

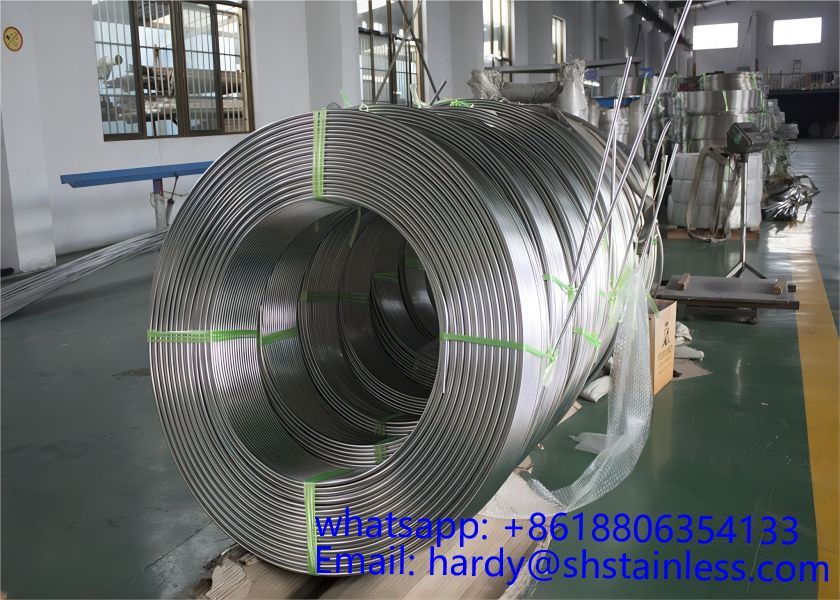

Liaochengsihe igwe anaghị agba nchara ihe Limited ụlọ ọrụ bụ ọkachamara emeputa kpọmkwem ahịa nke igwe anaghị agba nchara coiled tube igwe anaghị agba nchara ọkpọkọ , igwe anaghị agba nchara condenser igwe anaghị agba nchara precision pipe.has abụọ mmepụta ahịrị nwere ike na-aga n'ihu mmanụ anwụrụ, akụrụngwa zuru okè.

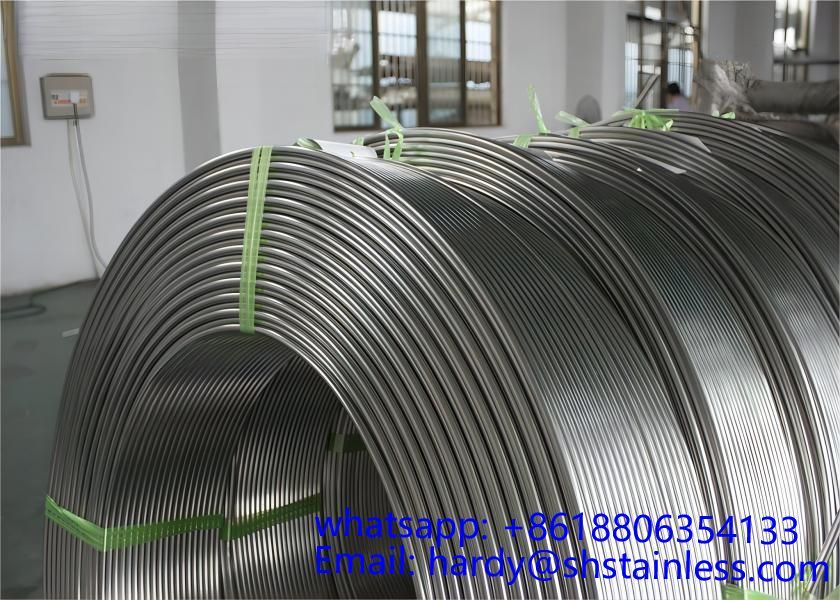

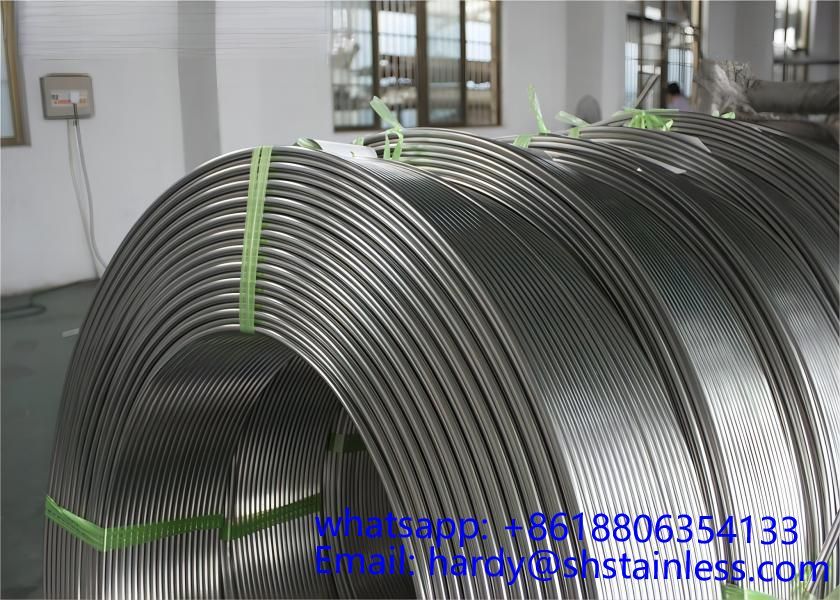

Foto ụlọ ọrụ

Nyocha

Mbupu & mbukota

Akụkọ nnwale